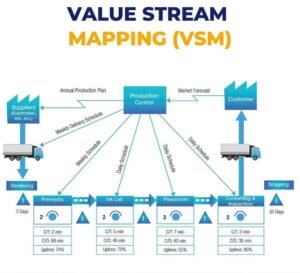

Value Stream Mapping (VSM) is one of the most powerful Lean tools used to visualize and improve the flow of materials and information from the start of a process to the final delivery to the customer.

It helps identify both value-added and non-value-added activities, allowing teams to spot waste (Muda) and make processes more efficient.

🔍 What It Does

VSM gives a big-picture view of how value moves through your organization — highlighting delays, rework, and bottlenecks. By mapping both the current state (how things work now) and the future state (how they should work), teams can plan structured improvements and create smoother workflows.

⚙️ Key Steps

- Select a product or service to map

- Observe and document the current process

- Identify waste and delays

- Design the improved future process

- Implement and review continuously

🚀 Benefits

- Reduces lead time and operational waste

- Improves process flow and efficiency

- Encourages teamwork and problem-solving

- Enhances customer value and satisfaction

🧭 Conclusion

Value Stream Mapping is more than just a diagram — it’s a way of seeing your entire process clearly. By focusing on the flow of value, organizations can transform complexity into clarity, eliminate waste, and build a culture of continuous improvement.

“You can’t improve what you can’t see — and VSM helps you see your process end to end.”