In Lean manufacturing and service systems, Kanban is one of the most effective tools for achieving smooth workflow, flexibility, and continuous improvement.

It helps teams visualize work, limit overload, and focus on just-in-time (JIT) production — producing only what’s needed, when it’s needed.

⚙️ What is Kanban?

The word “Kanban” is Japanese for “visual signal” or “card.”

In Lean terms, it’s a visual scheduling system that controls the flow of materials and information through a process.

Each Kanban card (physical or digital) represents a task, part, or product, signaling when new items should be produced or moved — preventing overproduction and ensuring steady flow.

🧩 How Kanban Works

Kanban operates on a pull system, meaning work is pulled through the process based on actual demand rather than pushed in advance.

When a product is consumed, a Kanban signal triggers replenishment — keeping inventory low and processes responsive.

Key Elements of Kanban:

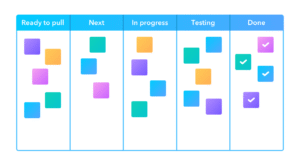

Visual Board: Displays work stages (e.g., To Do → In Progress → Done)

Kanban Cards: Represent work items and track progress

WIP Limits (Work-In-Progress): Restrict how many tasks can be in progress at once to maintain flow

Continuous Improvement: Regular review to identify and eliminate bottlenecks

🚀 Benefits of Kanban

- Improves workflow visibility and control

- Reduces overproduction and waiting time

- Enhances team coordination and communication

- Enables faster response to customer demand

- Promotes continuous improvement and adaptability

🧭 Conclusion

Kanban is more than a board full of cards — it’s a mindset of flow, flexibility, and focus.

By visualizing work and limiting overload, teams can achieve smoother processes, faster delivery, and greater customer satisfaction.

“When you can see the flow, you can improve the flow — that’s the essence of Kanban.”