Every organization runs on processes — but not every process runs efficiently.

That’s where Process Mapping comes in. It’s a powerful Lean tool that helps teams visualize, analyze, and improve the way work actually happens.

⚙️ What is Process Mapping?

Process Mapping is the visual representation of a workflow — showing each step, decision point, input, and output from start to finish.

It helps uncover waste, redundancies, and bottlenecks that often go unnoticed in daily operations.

“If you can’t see the process, you can’t improve it.”

🧩 Types of Process Maps

High-Level (SIPOC) Map:

Shows the overall process with Suppliers, Inputs, Process, Outputs, and Customers.

Detailed Flowchart:

Captures every action, decision, and handoff in a process.

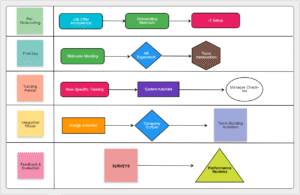

Swimlane Diagram:

Displays who is responsible for each step, highlighting cross-functional roles.

🔍 Why Process Mapping Matters

Identifies non–value-added steps and waste

- Improves clarity and communication among teams

- Serves as a baseline for standardization and improvement

- Helps design smoother, more efficient workflows

🚀 Benefits

- Reduces errors and delays

- Increases transparency and accountability

- Improves process efficiency and customer satisfaction

- Builds a foundation for continuous improvement (Kaizen)

🧭 Conclusion

Process Mapping is more than drawing boxes and arrows — it’s about seeing reality clearly.

By understanding how work truly flows, organizations can eliminate waste, optimize performance, and create processes that deliver consistent value.

“Clarity leads to improvement — and Process Mapping provides that clarity.”